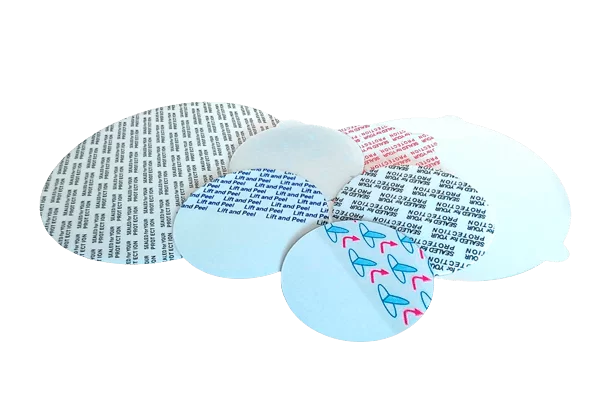

One of the customary ways to improve the cap’s sealing of the bottle or jar is with the insertion of a seal into the cap. The seal has several functions:

We provide a wide variety of seals (liners), which we import from the leading manufacturers in Europe and the USA. All of the seals have been approved for contact with food and pharmaceuticals according to the European and American standards:

Our aluminum liners come with a tab for the convenient lifting and detachment of the liner from the jars’ mouth upon the first opening: Lift N’ Peal.

You can order a larger variety of seals upon request: aluminum liners with cardboard backing, aluminum liners with your logo printed on them, etc., EPE liners with cardboard backing, silicon liners, and more.

What are seals and liners for closures and caps?

Seals and liners are thin materials that are placed between a container and its closure or cap. They help to create a tight seal, preventing leaks, contamination, and oxidation of the product inside the container.

What types of seals and liners does Gil Pack offer?

Gil Pack offers a wide range of seals and liners, including induction liners, foam liners, pressure-sensitive liners, heat-seal liners, and more. These are available in different materials, such as PET, HDPE, aluminum foil, and pulpboard, and can be customized according to the customer’s requirements and according to the material that the bottle or jar are made of.

What are induction liners?

Induction seals are a type of liner that creates a hermetic seal when heated by an induction sealing machine. The seal is created between the container and the closure, and provides tamper-evident protection, as well as preventing leaks and preserving the freshness of the product.

What are foam liners?

Foam liners are made of a compressible foam material, such as polyethylene or polyurethane, and are designed to create a barrier between the closure and the container. They provide a cushioning effect that is creating a tight seal that prevents leaks

How do I choose the right seal or liner for my product?

The choice of seal or liner depends on the type of product, the container material, and the closure or cap design. Gil Pack’s team of experts can help you to select the most appropriate seal or liner for your specific needs.

Can Gil Pack customize seals and liners?

Yes, Gil Pack can customize seals and liners according to the customer’s requirements, including size, shape, material, and printing. Customization allows customers to enhance their brand image and ensure the best possible protection for their products.

What is the minimum order quantity for seals and liners?

The minimum order quantity for seals and liners depends on the type of product and the customization requirements. Please contact Gil Pack’s sales team for more information.

How can I order seals and liners from Gil Pack?

You can order seals and liners from Gil Pack by visiting the website and selecting the desired product, or by contacting the sales team directly via phone or email.

Looking to purchase this product? Contact us today to find the perfect solution tailored to your needs